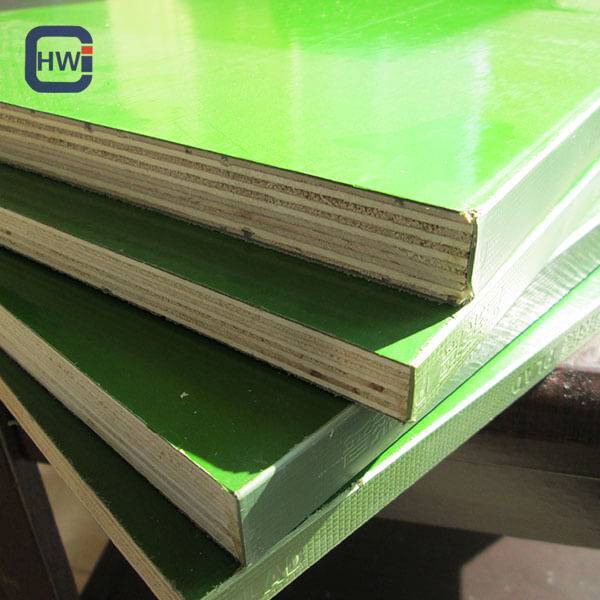

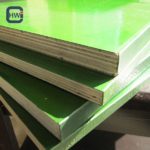

Green PP Plastic Faced Plywood

Product Details of Green PP Plastic Faced Plywood:

PP plastic coated plwood panels are made of wear-resisting and corrosion resisting 0.5mm thickness PP Plastic on both of sides coating and connecting to inner plywood core.

Here the physical and mechanical properties are much higher than traditional film faced plywood. This results in excellent properties:

• high mechanical cohesiveness

• high abrasion resistance

• water and weatheproof

• reusability(more than 30 times)

• excellent chemical resistance

• recyclable

Now,our PP Plastic Coated Plywood have been using widely in construction field around the world, such as Southeast Asia, Middle East, Europe markets.

Description of Green PP Plastic Faced Plywood:

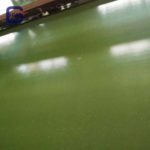

More better waterproof

This plastic is PP. Full name of PP is polypropylene.

The physical properties of polypropylenes are: corrosion resistance, acid and alkali resistance, hardness.

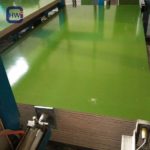

Perfect concrete wall For its wear resistance, it will be always easy to release and the surface will be always bright. While, the normal film faced plywood performs well only for one or two times. But after using two times, it will hard to release for the surface wear during the using process. And the surface will be damaged which will lead to the rough surface.

| Length | 2440-2500mm |

| Wide | 1220-1250mm |

| Thickness | 12-15-18-21mm |

MAJOR ADVANTAGES OF PLASTIC PLYWOOD

1. Easy to dismount,release agent free,nonstick cement,smooth finishing.

2. Light in weight,easy to use,can be cut to various size.

3. More reuse times than normal film faced plywood.

4. Waterproof performance and wear & tear resistant.

Delivery Instructions of Green PP Plastic Faced Plywood:

| Packing | Standard Export Pallet Packing | Inner Packing | Pallet is wrapped with a 0.20mm plastic bag | |

| Outer Packing | Pallet is covered with plywood or carton and then PVC/steel tapes for strength | |||

| Loading Quantity | 20’GP | 8pallets/22cbm | ||

| 40’GP | 16pallets/42cbm | |||

| 40’HQ | 18pallets/50cbm | |||

Packaging and Containerization of Green PP Plastic Faced Plywood:

Application of Green PP Plastic Faced Plywood:

Green PP Plastic Faced Plywood used for Construction, Formwork Syetem etc.