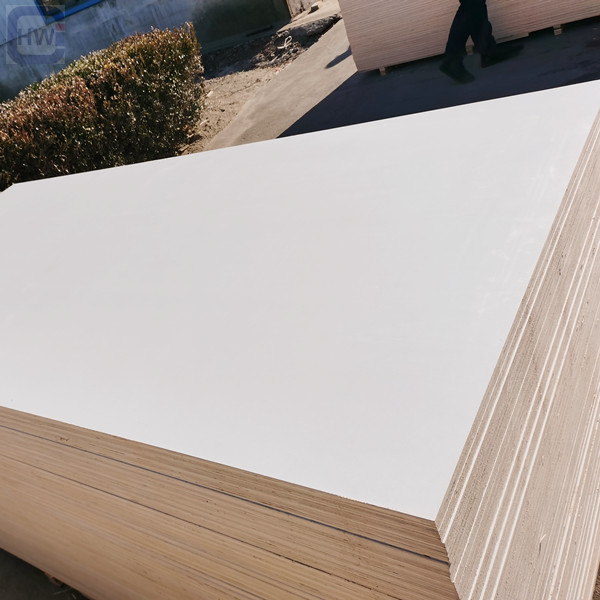

Melamine Paper Plywood

Product Details of Melamine Paper Plywood:

Quick read of melamine plywood

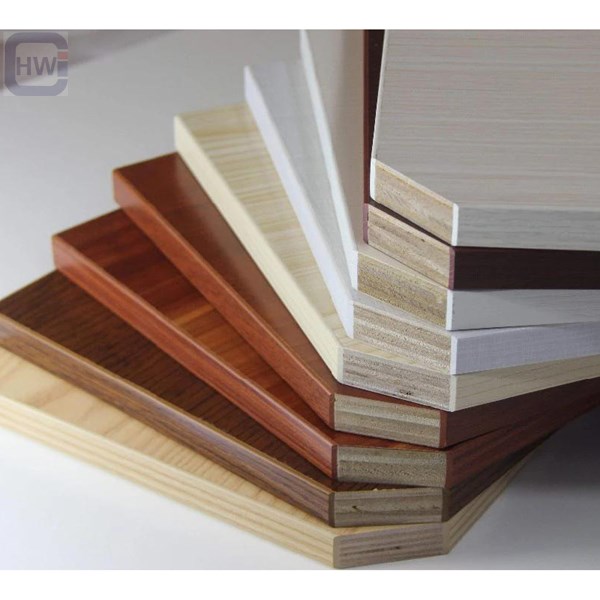

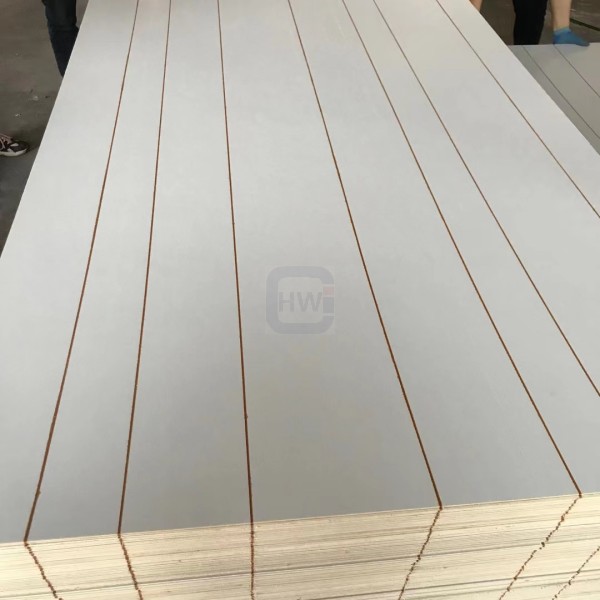

Melamine plywood is the ideal material for the furniture, interior decoration ,floor and so on . It has the characteristics of pollution-free,scratch resistant ,heat resistant and moisture-proof ,while retaining the original wood structure.Its features provide high visual quality with smooth and superior surfaces that are ready for use.The color of melamine can be solid color such as white, black,gray.

Wood grain color such as oak ,sapele,teak ,cherry . cloth grain and marble grain. The core we choose from high quality full pieces poplar ,birch or Eucalyptus veneer to make sure the plywood with uniform thickness, super flat surface and high bending strength . Melamine paper also can apply on MDF ,chipboard and blockboard.

Basic Parameters of Melamine Paper Plywood:

| Product Name | HW Melamine Paper Faced Plywood/Board | ||

| Size | 1220x2440mm/1250x2500mm/ or as clients requirement | ||

| Thickness | 3-30mm | ||

| Thickness Tolerance | +/-0.2mm (thickness<6mm), +/-0.3~0.5mm (thickness≥6mm) | ||

| Face/Back | Melamine Paper 180-220g/m2 and color as clients requirement | ||

| Core | Plywood, Block Board, MDF, PB Board | ||

| Glue | E0, E1, E2, MR, Melamine or WBP | ||

| Hot Press | Direct and Composite faced | ||

| Density | 520~700kg/m3 | ||

| Technical Parameters | Moisture Content | <12% | |

| Water Absorption | ≤10% | ||

| Modulus of Elasticity | ≥5000Mpa | ||

| Static Bending Strength | ≥30Mpa | ||

| Surface Bonding Strength | ≥1.60Mpa | ||

| Internal Bonding Strength | ≥0.90Mpa | ||

| Screw Holding Ability | Face | ≥1900N | |

| Edge | ≥1200N | ||

| Usage & Performance | Plywood is widely used for Automotive Interior ,furniture, decoration, construction and packing. With good properties, such as, easy fabricability, high bending strength, strong screw holding ability, heat resistant, anti-static, long-lasting and no seasonal effect. | ||

| MOQ | 1x20’FCL | ||

| Supply Ability | 5000cbm/month | ||

| Payment Terms | T/T or L/C at sight | ||

| Delivery Time | Within 20 days after receiving deposit or original L/C at sight | ||

| Certification | CE, FSC, EUTR, CARB,EPA, JAS, ISO | ||

Technical Parameters of Melamine Paper Plywood:

| Moisture Content | 8%~14% | |

| Modulus of Elasticity | ≥2500Mpa | |

| Static Bending Strength | ≥22Mpa | |

| Surface Bonding Strength | ≥1.20 Mpa | |

| Internal Bonding Strength | ≥0.55 Mpa | |

| Screw Holding Ability | Face | ≥1300N |

| Edge | ≥800N | |

Surface Species

Delivery Instructions of Melamine Paper Plywood:

| Packing | Standard Export Pallet Packing | Inner Packing | Pallet is wrapped with a 0.20mm plastic bag | |

| Outer Packing | Pallet is covered with plywood or carton and then PVC/steel tapes for strength | |||

| Loading Quantity | 20’GP | 8pallets/22cbm | ||

| 40’GP | 16pallets/42cbm | |||

| 40’HQ | 18pallets/50cbm | |||

Packaging and Containerization of Melamine Paper Plywood:

Application of Melamine Paper Plywood:

Melamine Paper Plywood for Furniture, counter tops, laminations, kitchens, and other interior work, as well as for other usages.