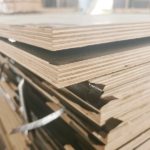

Phenolic Film Faced Birch Plywood

Birch Film Faced Plywood

Birch Film Faced plywood is approved solution in need of a top quality formwork plywood. Its film is flat both sides, I/I quality. Panels are available in different thickness from 9 to 21 mm. The birch veneer used achieves the plywood high resistance to load, proven product strenght. Its maximum use (cycles count) in terms of regular use, overpay several times the investment made for buying it.

Film faced plywood is lightweight, resistant to corrosion attack and water, easily combined with other materials and easy to clean and cut.Treating the film faced plywood’s edges with waterproof paint makes it highly water-and wear-resistant. Due to its durability and easily handled surface it can be used in open environment in construction and building.

Coating the film faced plywood with high-quality import films ensures hardness and damage resistance.

The surface of the film faced plywood is hygienic and resistant to strong detergents.

It can be used in conditions of high temperature drop, influence of moisture, detergent cleaning and provides protection against termites.

We offer two types of film faced plywood. The first being birch film faced plywood which is very resistant to water, easy to clean and cut and one of the world’s best quality plywood’s.The second is poplar film faced plywood. This plywood type is also easy to clean and cut and is softer and lighter material than birch film faced plywood.

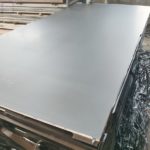

Product Name: Birch Film Faced Plywood

1). Face and Back:

Black ( Dynea ) color film, Brown ( Dynea ) color film, Red ( Dynea ) color film, PP Plastic or other colors upon request

2). Species Of Core Veneers:

Birch, Poplar, Hardwood , Combi

3). Glue:

Phenolic-WBP, Melamine-WBP

4). Sizes:

Width: 1200mm, 1220mm, 1250mm, 1500mm, 1525mm, 1800mm, 1830mm, 2000mm or other width no more than 2000mm;

Length: 2400mm, 2440mm , 2500mm, 3000mm, 3050mm, 3600mm, 3660mm, 4270mm, 4575mm, 4880mm, 5185mm or other length no more than 6000mm;

5). Thickness:

9mm / 12mm / 15mm / 18mm / 21mm / 24mm / 27mm (1/8″, 1/4″, 3/8″, 1/2″, 5/8″, 3/4″, 1″, 1-1/8″ 1-1/4″, 1-1/2″ ) or other thickness no more than 50mm

6) Edge:

Sealed by water-proof paint

Advantages of Birch Film Faced Plywood:

1) The phenolic glue of the film faced plywood can smooth the surface of concrete; If one side is anti-slip, Mesh surface provides anti-slip protection

2) High Wear-Resistant, Anti-Cracking, Alkaline-Resistant, Anti-Abrasive, Anti-erosive;

3) Resistant to the effect of various environments, including chemicals, Resistance to temperature variation -40 to +50 °C

4) The water-proof coating and estend the working life of the concrete;

5) There is no color contamination between the concrete and the concrete shuttering plywood;

6) Low levels of aldhyde, phenol, and other toxic emissions;

7) The product can be cut to small size to use again if it is cut, please spray waterproof paint on the edges which have been cut;

8) Birch core, Combi core plywood is more firmly than poplar core, and the best core is Birch.

Delivery Instructions of Birch Film Faced Plywood:

| Packing | Standard Export Pallet Packing | Inner Packing | Pallet is wrapped with a 0.20mm plastic bag | |

| Outer Packing | Pallet is covered with plywood or carton and then PVC/steel tapes for strength | |||

| Loading Quantity | 20’GP | 8pallets/22cbm | ||

| 40’GP | 16pallets/42cbm | |||

| 40’HQ | 18pallets/50cbm | |||

Packaging and Containerization of Birch Film Faced Plywood:

Application of Birch Film Faced Plywood:

Birch Film Faced Plywood widely use for Construction, Formwork Syetem, vehicle floors, flight cases,ship decking, transport platforms etc.