Products

-

Recon Veneer

- Recon Veneer

- Loading Quantity: 20’GP-8pallets/22CBM, 40’HQ-14pallets/50CBM

- MOQ: 1X20’FCL

- Supply Ability: 5000CBM/Month

- Payment Terms: T/T or L/C

- Delivery Time: Within 20 days after deposit confirmation

- Certification: CE, FSC, EUTR, CARB,EPA, JAS, ISO

- Material: Sliced Veneer/Engineered Veneer/custom

- Size:1270*2500mm,1270*2200mm, 1270*1900mm,970*200mm, 970*1900mm or customize

- Thickness: 0.15mm-1.5mm

- Glue: E0/E1

- Formaldehyde Release: E0≤0.5mg/L, E1≤1.5mg/L, E2≤5.0mg/L

- Moisture Content: <20%

-

Red Face Veneer Decorative Natural Wood Okoume Veneers Gabon

- Loading Quantity: 20’GP-8pallets/22CBM, 40’HQ-14pallets/50CBM

- MOQ: 1X20’FCL

- Supply Ability: 5000CBM/Month

- Payment Terms: T/T or L/C

- Delivery Time: Within 20 days after deposit confirmation

- Certification: CE, FSC, EUTR, CARB,EPA, JAS, ISO

- Material: Okoume Veneer/Rotary Cut Veneer/custom

- Size:1270*2500mm,1270*2200mm, 1270*1900mm,970*200mm, 970*1900mm or customize

- Thickness: 0.15mm-1.5mm

- Moisture Content: <12%

-

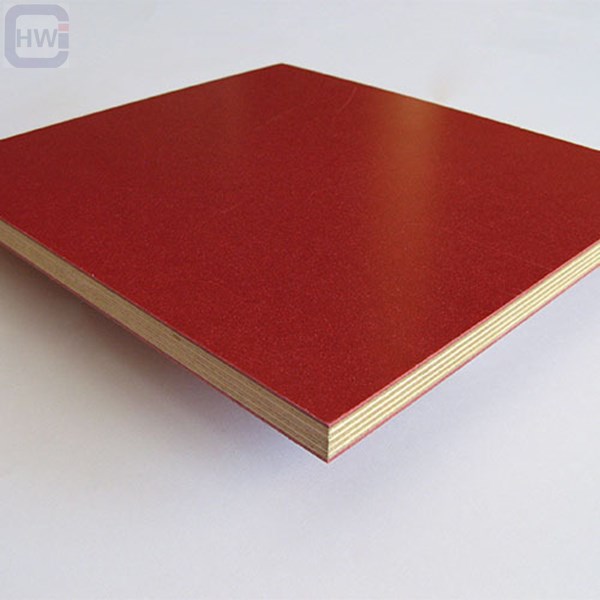

Red Film Faced Plywood

Film Faced Plywood is also called Formwork Plywood, Shuttering Plywood, Concrete formwork. Film faced plywood is the special plywood with two sides coated with wearable and water proof film. The film is adhesive impregnated paper, which are different from melamine paper overlay, PVC, MDO and HDO. The function of the film is to protect the inside wood from moisture, water, weather and extend the plywood’s service life. Film Faced Plywood is an exterior plywood used in building and construction projects……

-

Red Oak Plywood

- Red Oak Plywood

- Loading Quantity: 20’GP-8pallets/22CBM, 40’HQ-18pallets/50CBM

- MOQ: 1X20’FCL

- Supply Ability: 5000CBM/Month

- Payment Terms: T/T or L/C

- Delivery Time: Within 20 days after deposit confirmation

- Certification: CE, FSC, EUTR, CARB,EPA, JAS, ISO

- Surface: red oak, ash, white oak, birch, maple, teak, sapele , cherry, beech, walnut and so on

- Size: 1220x2440mm/1250x2500mm/custom

- Thickness:3–30mm/custom

- Glue:E0/E1/E2/Custom

-

Red Oak Plywood

- Red Oak Plywood

- Loading Quantity: 20’GP-8pallets/22CBM, 40’HQ-18pallets/50CBM

- MOQ: 1X20’FCL

- Supply Ability: 5000CBM/Month

- Payment Terms: T/T or L/C

- Delivery Time: Within 20 days after deposit confirmation

- Certification: CE, FSC, EUTR, CARB,EPA, JAS, ISO

- Surface: red oak, ash, white oak, birch, maple, teak, sapele , cherry, beech, walnut and so on

- Size: 1220x2440mm/1250x2500mm/custom

- Thickness:3–30mm/custom

- Glue:E0/E1/E2/Custom

-

RV AND CARAVAN LIGHT WEIGHT PLYWOOD

- RV AND CARAVAN LIGHT WEIGHT PLYWOOD

- Loading Quantity: 20’GP-8pallets/22CBM, 40’HQ-18pallets/50CBM

- MOQ: 1X20’FCL

- Supply Ability: 5000CBM/Month

- Payment Terms: T/T or L/C

- Delivery Time: Within 20 days after deposit confirmation

- Certification: CE, FSC, EUTR, CARB,EPA, JAS, ISO

- Face/Back: Recon Veneer/custom

- Core: Paulownia Veneer or Paulownia Blockboard

- Size: 1220x2440mm/1230x2520mm/custom

- Thickness: 12mm/16MM/custom

- Glue:E0/E1/E2/Custom

- Formaldehyde Release: E0≤0.5mg/L, E1≤1.5mg/L, E2≤5.0mg/L

- Density: 380-420KGS/CBM

- Moisture Content: <12%

-

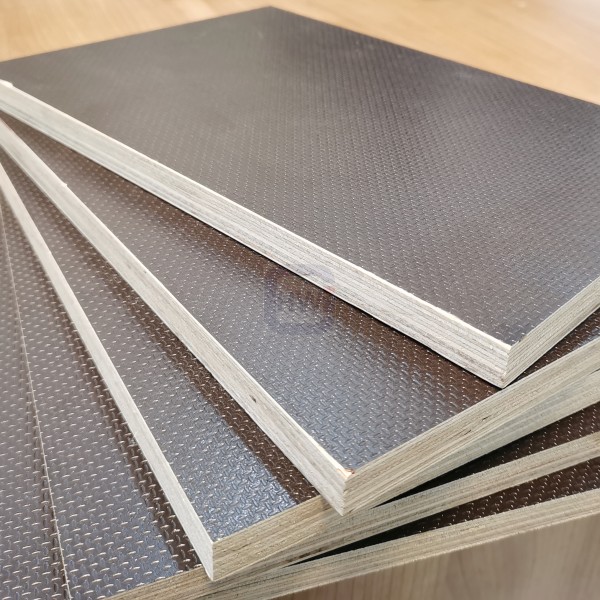

Slip-Resistant Flooring Plywood

Anti-slip Plywood is an Engineered Plywood with high quality and applicability, Coated With Brown, Black, Red Or Gray Film. The patterned phenolic film surface is semi-glossy, hard and resistant to impact and abrasion. Its widely used for House Building, Road Construction, Concrete Project, Scaffolding, Bridge Beams, and all kind of Flooring ( In The Transportation Industry, The Heavy Duty Pattern Face Gives Superlative Slip Resistance).

-

Slip-Resistant Flooring Plywood

Anti-slip Plywood is an Engineered Plywood with high quality and applicability, Coated With Brown, Black, Red Or Gray Film. The patterned phenolic film surface is semi-glossy, hard and resistant to impact and abrasion. Its widely used for House Building, Road Construction, Concrete Project, Scaffolding, Bridge Beams, and all kind of Flooring ( In The Transportation Industry, The Heavy Duty Pattern Face Gives Superlative Slip Resistance).

-

Structural LVL Timber

Laminated veneer lumber (LVL) is an engineered wood product that uses multiple layers of thin wood assembled with adhesives . It is typically used for headers, beams, rimboard, and edge-forming material. LVL offers several advantages over typical milled lumber: Made in a factory under controlled specifications, it is stronger, straighter, and more uniform. Due to its composite nature, it is much less likely than conventional lumber to warp, twist, bow, or shrink. LVL is a type of structural composite lumber, comparable to glued laminated timber (glulam) but with a higher allowable stress.

-

Structural LVL, Laminated Veneer Lumber (LVL) Engineered Wood

Laminated veneer lumber (LVL) is an engineered wood product that uses multiple layers of thin wood assembled with adhesives . It is typically used for headers, beams, rimboard, and edge-forming material. LVL offers several advantages over typical milled lumber: Made in a factory under controlled specifications, it is stronger, straighter, and more uniform. Due to its composite nature, it is much less likely than conventional lumber to warp, twist, bow, or shrink. LVL is a type of structural composite lumber, comparable to glued laminated timber (glulam) but with a higher allowable stress.

-

Truck Antislip Plywood

Truck Antislip Plywood is an Engineered Plywood with high quality and applicability, Coated With Brown, Black, Red Or Gray Film. The patterned phenolic film surface is semi-glossy, hard and resistant to impact and abrasion. Its widely used for House Building, Road Construction, Concrete Project, Scaffolding, Bridge Beams, and all kind of Flooring ( In The Transportation Industry, The Heavy Duty Pattern Face Gives Superlative Slip Resistance).

-

Truck Antislip Plywood

Truck Antislip Plywood is an Engineered Plywood with high quality and applicability, Coated With Brown, Black, Red Or Gray Film. The patterned phenolic film surface is semi-glossy, hard and resistant to impact and abrasion. Its widely used for House Building, Road Construction, Concrete Project, Scaffolding, Bridge Beams, and all kind of Flooring ( In The Transportation Industry, The Heavy Duty Pattern Face Gives Superlative Slip Resistance).